DISCOVER ABOUT

Atlanta stretch

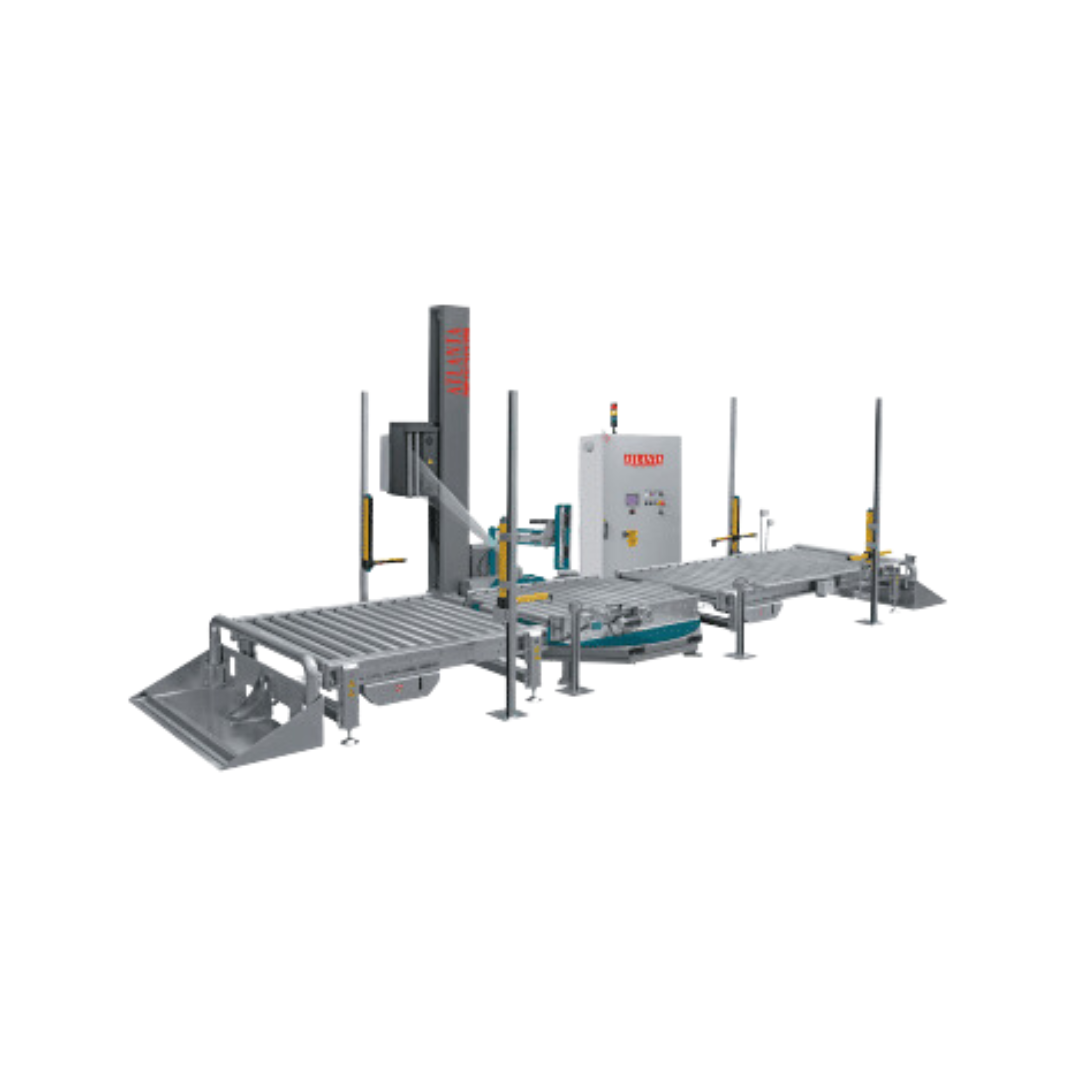

Atlanta Stretch SpA are specialists in the design, construction and manufacturing of automatic and semi-automatic pallet stretch wrapping machines. This includes integrating our machines into complex production lines, specially developed to automate the complete packaging process.

The company was founded by Mr. Angelo Forni in 2005. He was also the founding father of various other important packaging companies during the 1980’s, all of which still exist in the market today.

Atlanta Stretch SpA has a range of patented systems, which are contributing to more advanced and economically sound solutions, all without compromising on quality or technical performance. The innovations we have introduced allow our stretch wrapping machines to be installed even more easily and therefore in less time. We have also designed them to take up less space, consequently they deliver reduced costs of installation and integration. All this adds to our ability to provide excellent value for money in the the overall costs of packaging in general.